Franklin pilot facility explores future of municipal water, wastewater services

By KATE COIL

TML Communications Specialist

A new, first-of-its kind water facility in Franklin is changing both how the city approaches water reuse and potentially how water and wastewater services operate across Tennessee.

Franklin’s water purification demonstration facility is finding new ways to use technology to treat water and wastewater, augment local water supplies, and provide stewardship of water resources. The research being done in Franklin is also being shared with the Tennessee Department of Environment and Conservation (TDEC) with the potential for its successes to be duplicated across Tennessee.

Michelle Hatcher, director of water management with the city of Franklin, said the concept for the pilot facility dates back to 2010 when the city created its Integrated Water Resources Plan looking at how Franklin’s growth and population would impact water services into 2040. It was determined the city would need a new wastewater plant on the south end.

“As we saw the need for that, we started talking about concerns we had like water scarcity in other places, how we can reduce our operating costs with more efficiency, and lowering the nutrients we put into the river. That is how the idea for this facility was developed,” Hatcher said. “We worked with TDEC to make sure we were going about it the right way. There weren’t regulations in place yet, so we worked with them on what those would be and what made sense.”

Construction started on the facility in February 2021 and the facility was opened October 2022 with operations beginning that same month. The facility is near both the Harpeth River and right across from the site of the new Southeast Wastewater Plant for the city.

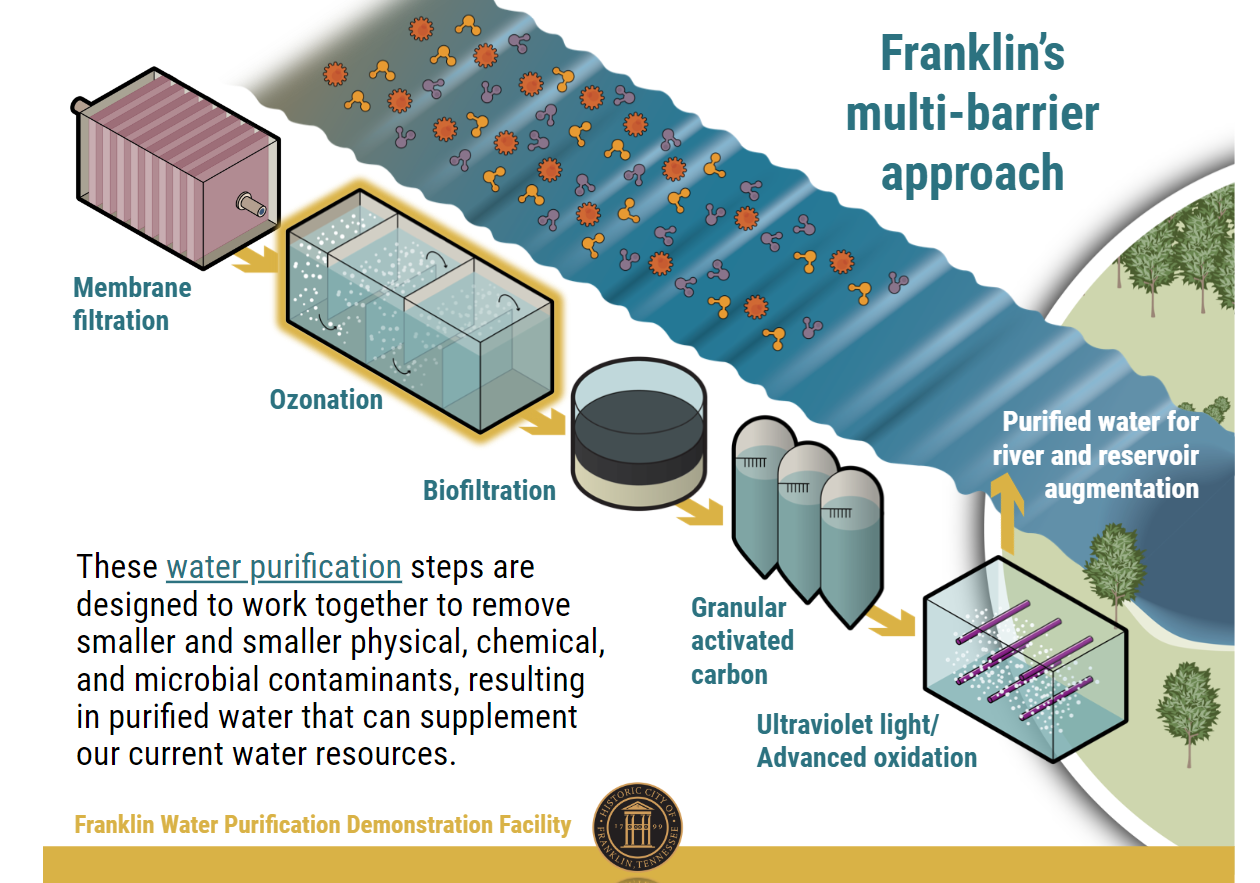

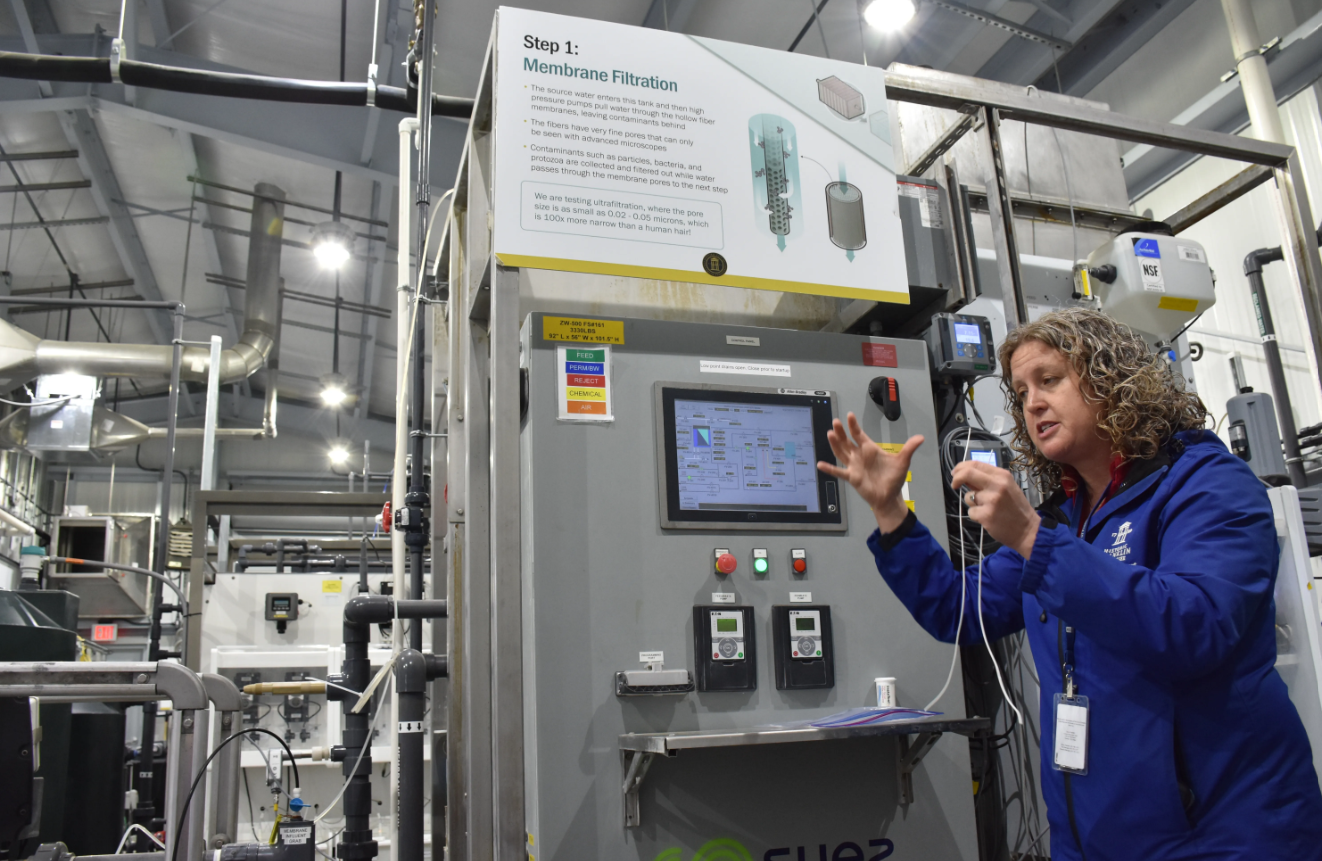

The facility has a five-step process of membrane filtration, ozonation, biofiltration, granular activated carbon, and finally ultraviolet disinfection with advanced oxidation. In the membrane filtration step, water is pumped at high pressure through hollow fiber membranes, leaving behind containments such as particles, bacteria, and protozoa.

“We have designed the facility with the ability to collect samples before and after each process,” Hatcher said. “That allows us to see the efficiency and efficacy of each process and how that can be ratioed up on a larger scale. We have the ability to test for parameters upstream and downstream of each process but to also bypass some processes as well to see how one process might affect the overall outcome of treated water. Through that we’ve collected 10,000 samples. We collect about 1,000 samples every week. We analyze some internally with our staff and send them to two external facilities. We use all of those data points to ratio up and design the future facility.”

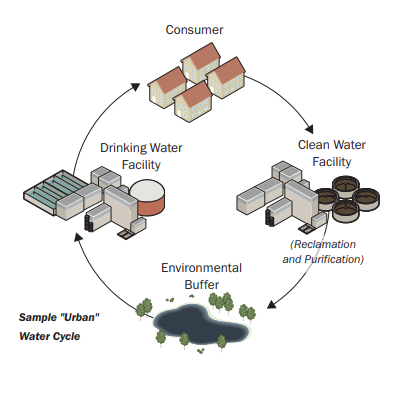

In addition to processes that will shape the future wastewater plant, the demonstration facility also can test to see if reuse samples would make safe drinking water. Hatcher said Franklin will work with TDEC by using the data points collected at the facility to see what the optimal reuse options for the treated water are.

“One of those options is taking total reuse that would be taking that directly into the drinking water system or putting it into the reservoir and treating it in water plants,” she said. “That will depend on how well we can treat drinking water.”

By reusing water in this way, Franklin would be able to save money for both rate payers and the city itself by ensuring more water is locally sourced.

“The city of Franklin is served by four different water districts,” Hatcher said. “In just the city’s service area, we have to purchase two-thirds of our water from a wholesaler because the water in the Harpeth cannot provide enough for our whole service area. If we had the ability to supply all or most of the water from what we already have, that would be huge for our customers in terms of savings, water quality, and reducing some of the capital outlay of maintenance costs we have.”

With water being a non-renewable resource, Hatcher said Franklin is not only readying itself for the future of water and wastewater but also getting to be part of the innovation that will shape that future.

“It is a lot more comfortable to do what we’ve always done, but we’ve started pushing that envelope a little bit,” Hatcher said. “It’s a hard conversation to have because there is a little bit of that yuck factor about people drinking wastewater, but really, it’s what we’re all drinking. We have led a public education campaign to show people. It’s been an investment that Franklin has had to make, but it’s an investment in our community and our sustainable operations, which is more beneficial to the community than not having that conversation.”

This is especially important as communities across the country and the world are struggling with both having enough water or having enough water that is safe for human consumption. She said many countries, like Singapore, have been using similar processes of water reuse for years because of the lack of availability of clean, drinkable water.

“We are not a water-scarce community yet; we aren’t like communities in Texas or California that really have water scarcity,” Hatcher said. “However, no one knows what things might look like in 20 or 30 years. Laying the groundwork for this is hugely beneficial for all of Tennessee. It helps TDEC write regulations and also shows other cities this is what we’ve done, this is what we can do, and this is what you can do to make it work in your community.”

Having the test facility operated by the city also has a different approach than might be seen in academia or in a private research lab.

“In Franklin, we are a very progressive community in the sense of fully vetting new technologies and not being afraid to try new technologies or be innovative,” Hatcher said. “I think this is an example of that. It is important to have a community that can show we can do this and make it cost effective for our customers, improve the quality of the Harpeth River, and improve the efficiency of our services."

In addition to preparing for the future of water, the facility is also helping Franklin train the next generation of water and wastewater treatment employees on the emerging technology that will become commonplace in the future.

“We have realized with the tours that we have given we have realized this is the next generation of water,” Hatcher said. “We have exemplified that by having a lot of young professionals working at the pilot facility because they will be operating the full-scale facility in 10 and 15 years. They will be the next leaders of our operations staff. We have also used a lot of the same technologies that have been there just in a different way. I think that’s a great thing to show other cities as well.”

Learn more about Franklin’s pilot facility and learn more about the processes the facility uses.